What we do..

Carib Prints offers laser graphics, 3D printing, label making, ribbon printing, button making, sublimation, and garment printing services as a versatile printing and manufacturing company that can cater to a wide range of customer needs. Here is a brief overview of what each of these services entails:

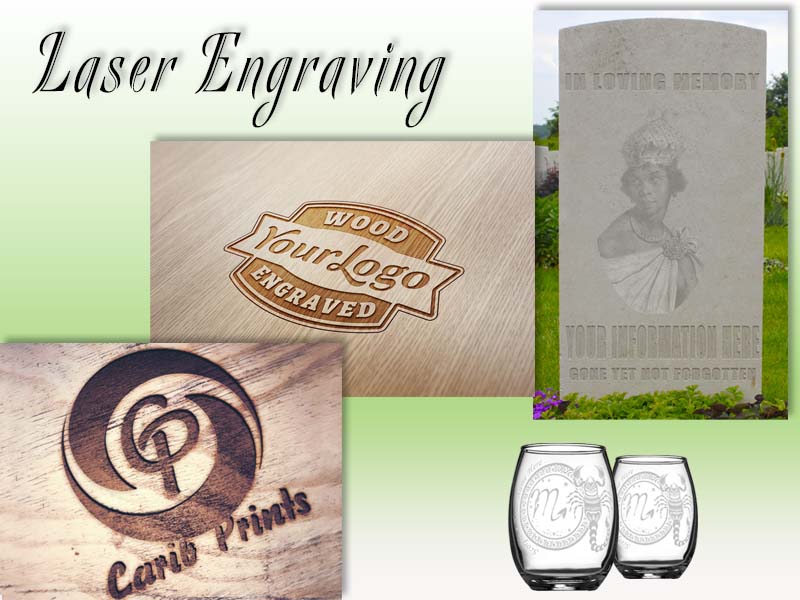

Laser graphics: This service involves using a high-powered laser to etch, engrave, or cut a wide variety of materials, such as wood, acrylic, metal, paper, and fabric. Laser graphics can be used to create intricate designs, logos, or text on products like awards, promotional items, signage, and personalized gifts.

3D printing: This service involves using a computer-aided design (CAD) software to create a digital model of a product or object, which is then printed layer by layer using a 3D printer. 3D printing can be used to make prototypes, custom-made parts, models, and even functional objects like prosthetics and medical implants.

Label making: This service involves creating adhesive labels that can be applied to products, packaging, or containers. Labels can be made in various shapes, sizes, and materials, such as paper, vinyl, polyester, or foil. Label making can be used to create product labels, barcodes, QR codes, warning labels, and more.

Ribbon printing: This service involves printing custom designs or text on ribbons, which can be used for gift wrapping, decorating, or branding purposes. Ribbons can be made in different colors, widths, and materials, such as satin, organza, or grosgrain.

Button Making: Button making is a process used to create buttons of various sizes and styles. Buttons are used in clothing, accessories, and even as decorative elements in home decor. The process of button making involves cutting a circular piece of material, imprinting a design or image onto the material, and attaching a metal or plastic backing to create the button. Button making has evolved over time with the introduction of new technologies such as laser cutting and 3D printing. These technologies have allowed for more intricate designs and faster production times.

Garment Printing: Also known as screen printing, is a process used to apply ink to textiles, such as t-shirts, hoodies, and tote bags. The process involves creating a stencil, or screen, of the design and then pressing ink through the stencil onto the fabric. This process can be used to create simple one-color designs or complex multi-color designs. Garment printing has become increasingly popular in recent years due to the rise of custom apparel and merchandise. Many businesses and organizations use garment printing to create branded clothing and accessories for their employees or customers. Additionally, many independent artists and designers use garment printing to create their own unique designs.

Sublimation: A printing process that involves the transfer of an image onto a substrate, such as fabric, ceramic or metal, using heat and pressure. The process involves using a special ink, called sublimation ink, which is printed onto transfer paper. The transfer paper is then placed onto the substrate and heat is applied, causing the ink to turn into a gas and then bond with the substrate. Sublimation printing is commonly used in the textile and promotional products industries to create custom t-shirts, mugs, phone cases, and other products. The process can be used on a variety of materials, including polyester, ceramic, and aluminum, and produces vibrant, long-lasting prints.

One of the advantages of sublimation printing is that it allows for full-color, high-resolution prints without the need for multiple screens or layers of ink. This makes it a cost-effective option for small runs or one-off designs. Additionally, the prints are durable and can withstand repeated washing and exposure to sunlight without fading or peeling. One limitation of sublimation printing is that it can only be used on materials that have a specific polymer coating. This means that it cannot be used on natural fibers, such as cotton or wool. Additionally, the process requires specialized equipment, including a sublimation printer, heat press, and sublimation ink. In conclusion, sublimation printing is a versatile and cost-effective printing process that produces high-quality, long-lasting prints on a variety of substrates. While it has some limitations, such as the materials it can be used on and the need for specialized equipment, it is a popular choice for custom apparel and promotional products due to the vibrancy and durability of the prints it produces.

Powder Coating: Powder coating is a process used to apply a dry powder to a surface. This process is commonly used in the automotive, aerospace, and construction industries to protect metal surfaces from corrosion and wear. The process involves applying an electrostatic charge to the powder particles and then spraying the powder onto a surface. The electrostatic charge causes the powder to adhere evenly to the surface, creating a smooth and durable finish. Powder coating has many advantages over traditional liquid coatings. It is more durable, resistant to chipping and scratching, and environmentally friendly. Additionally, powder coating can be applied in a variety of colors and finishes, including metallic, gloss, and matte.

In conclusion, the above-mentioned procedures are all important processes used in manufacturing and design. Each process has its own unique set of techniques, tools, and materials, and can be used to create a wide range of products. Whether you are protecting metal surfaces from corrosion, creating custom buttons, or printing your own designs on textiles, these processes offer endless possibilities for creativity and innovation.

Our comitment is to provide a strong focus on customer satisfaction. We can also offer design and consultation services to help customers create custom products that meet their specific needs and budget. Additionally, we offer fast turnaround times, and shipping options to make the process as convenient as possible for our customers.